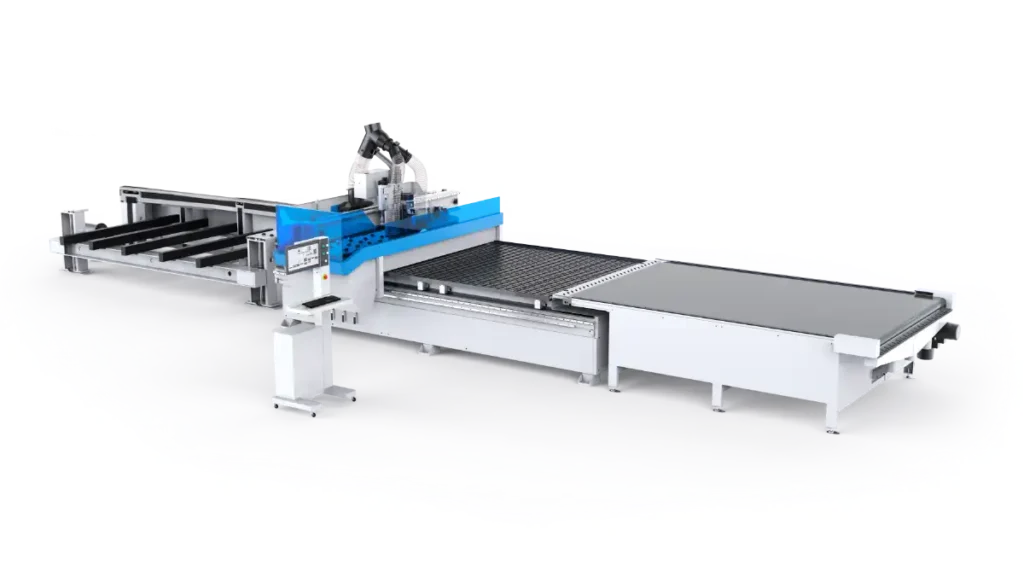

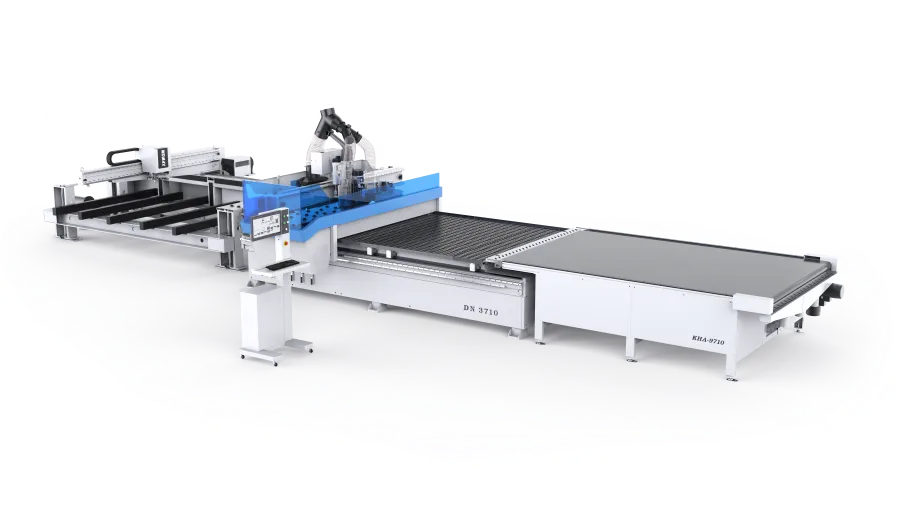

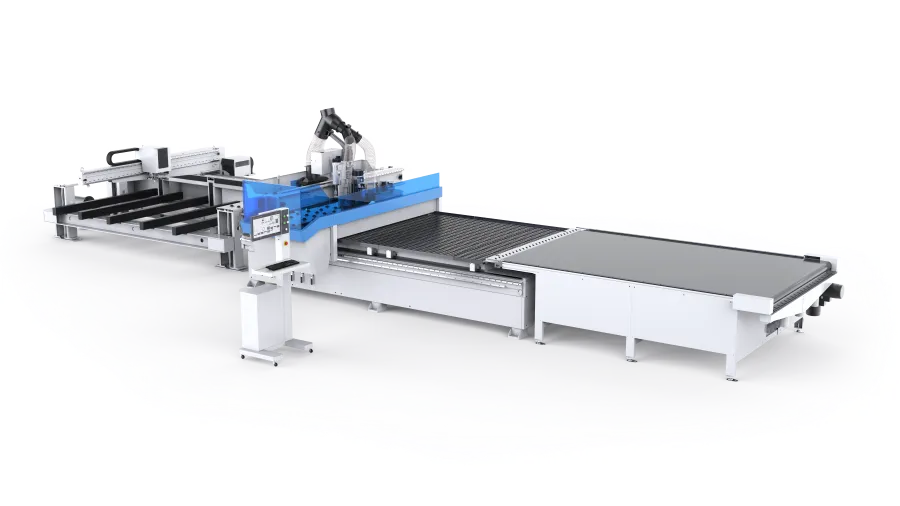

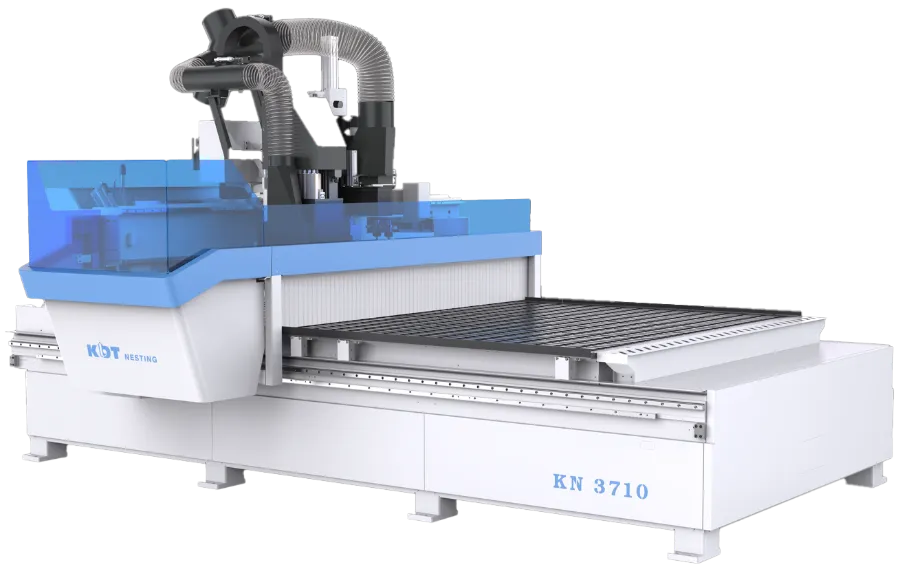

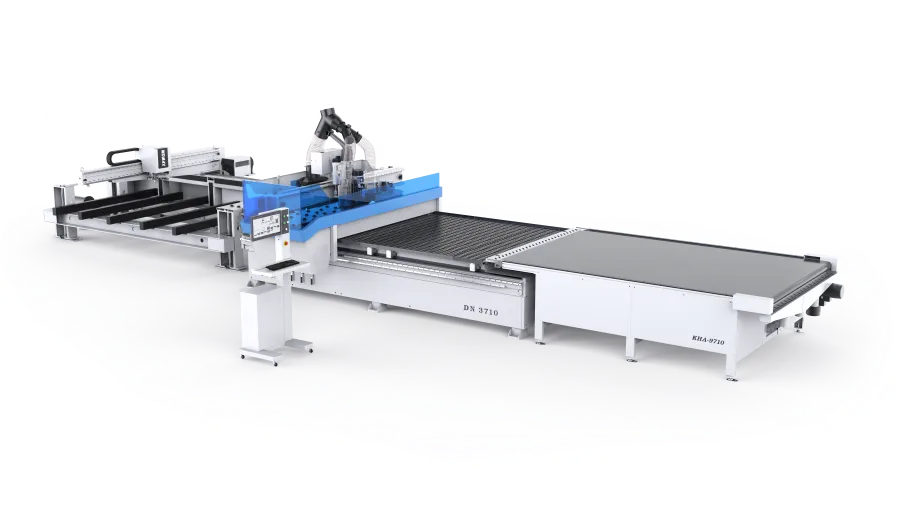

KN-3710DE machining centre KN-3710DE Loading and unloading with labelling machine

Description

CNC KDT KN-3710D 3100X2150MM. NESTING COMPLETO CON MESAS DE CARGA Y DESCARGA CON ETIQUETADORA

STRUCTURE

High-strength rigid frame.

Proper heat treatment ensures long-term accuracy.

REINFORCED VACUUM

Innovative design of the vacuum chamber which is actually part of the machine frame and significantly improves vacuum distribution. With 6 vacuum zones.

GANTRY

El Gantry está impulsado por 2 potentes servomotores vinculados electrónicamente.

El movimiento se realiza por un sistema de piñón y cremallera de 30 mm de alta resistencia.

1500W SERVO MOTORS allow very high accelerations and speeds.

Servomotors offer direct-driven linear movements and linear sliders.

They offer accurate positioning at high speed, smooth and vibration-free operation and very easy installation.

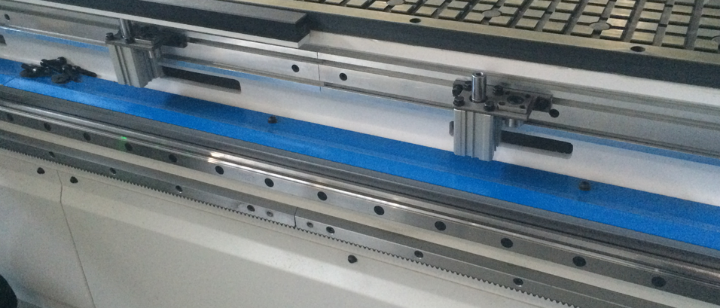

HELICAL RACK

Smooth running rack and pinion with low friction. Low noise and long-lasting precision.

The helical rack and pinion system ensures that the rack teeth are fully engaged at all times.

LINEAR GUIDES

The linear guides are lubricated by a centralised lubrication system. Reduced friction, energy consumption with extended service life.

Milling head 13.2kW

Milling unit mounted on the Z-axis.

- Potencia de electro motor: 12kW con refrigeración por aire.

- Tool locking device: automatic with pneumatic piston.

- Aluminium alloy engine body

- Attack with cones HSK-F63

Automatic tool calibration sensor

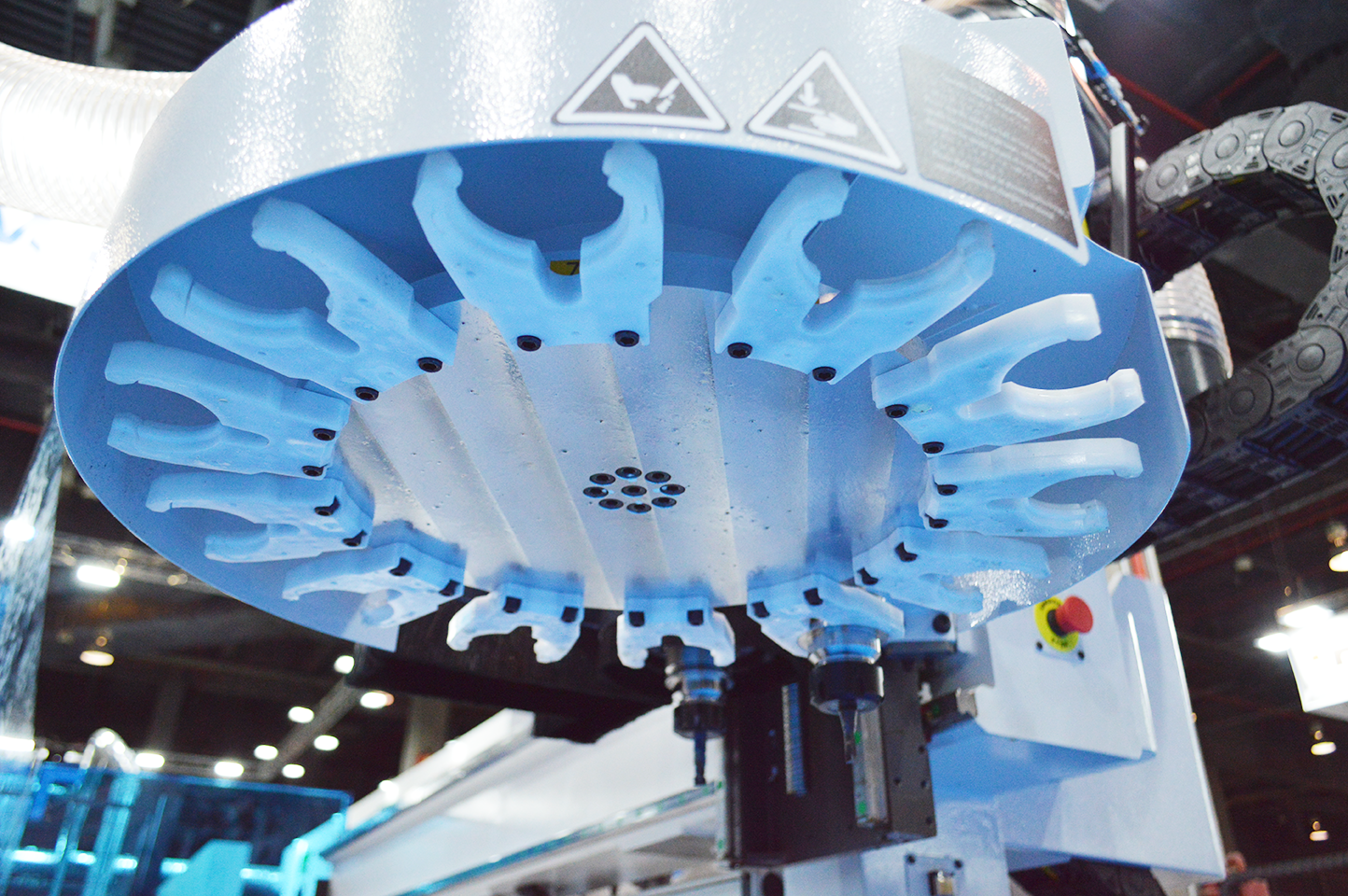

12-position revolver shift

Automatic linear magazine with 12 positions for main milling units, with HSK-F63 coupling. On/off movement with pneumatic cylinder. Fast automatic tool change with servo, high stability and precision.

Group of vertical drills

Work unit for vertical drilling with 10 drill bits.

Made of light aluminium alloy with high mechanical properties. Pre-selection is automatic by means of pneumatic pistons.

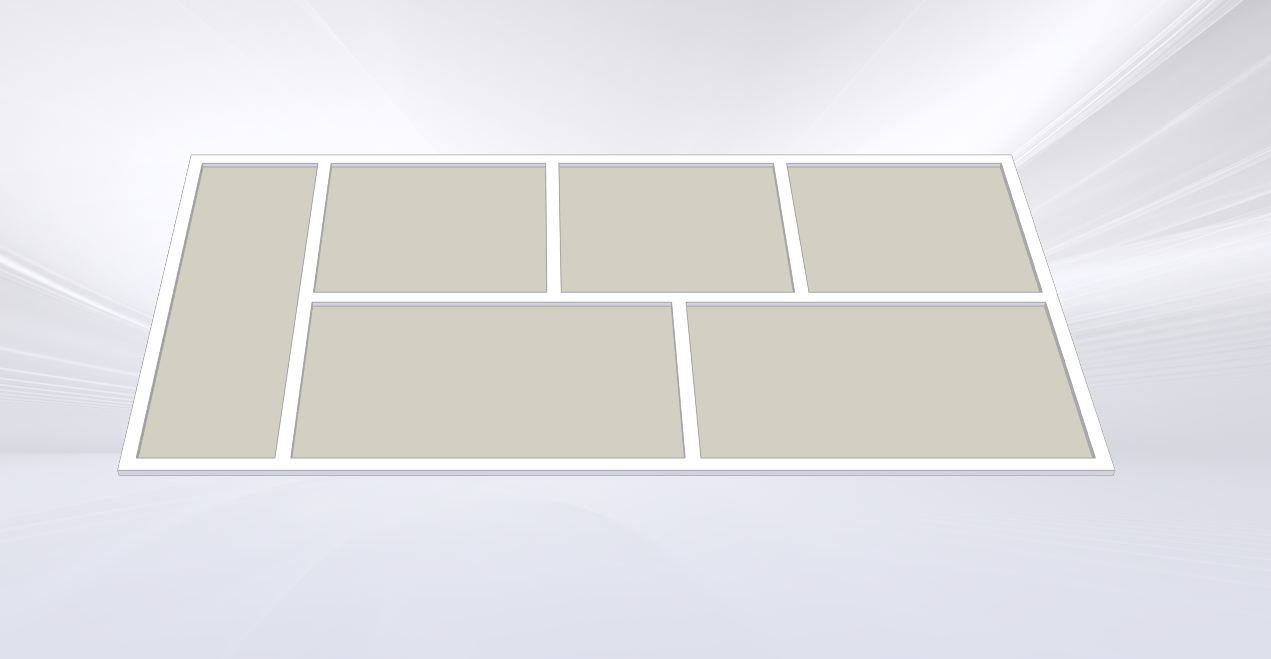

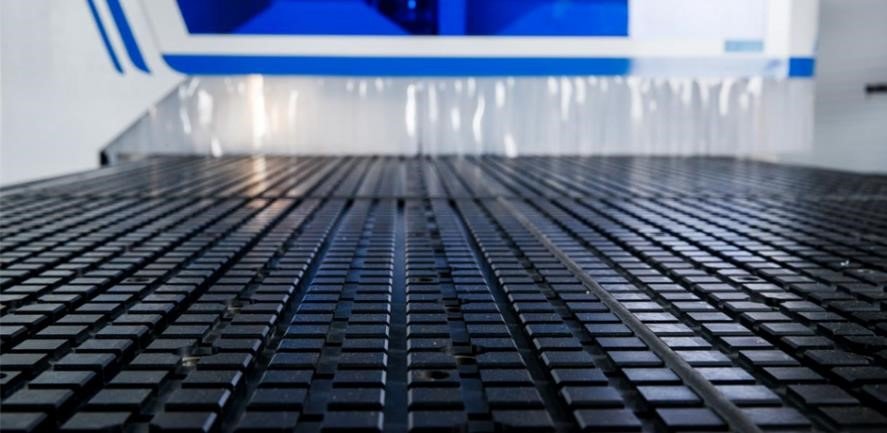

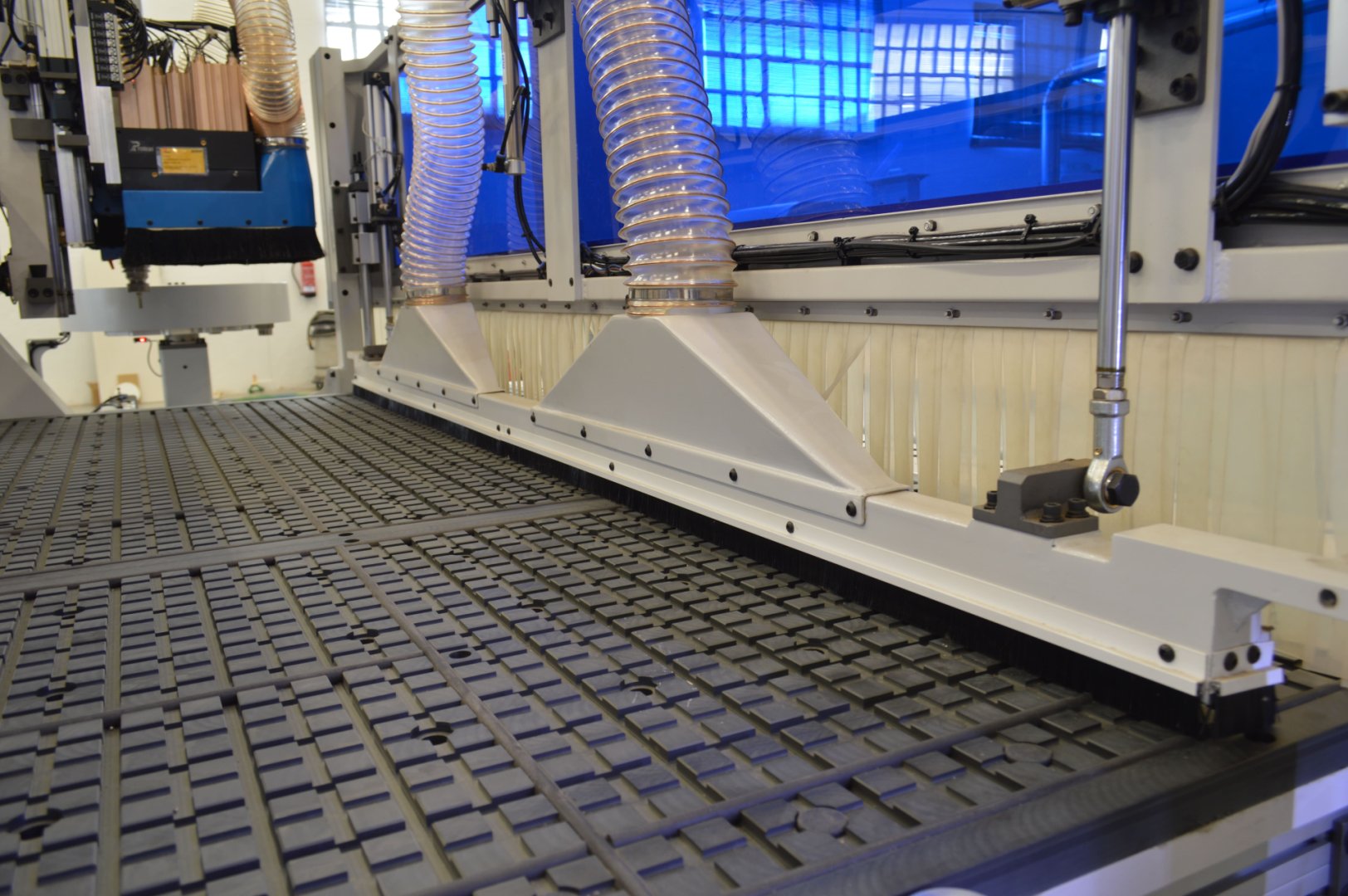

Vacuum table

Vacuum resin table, a highly wear-resistant material with a very fine surface finish that facilitates the sliding positioning of parts.

The table is fixed directly on the machine bed, which gives the machine high rigidity and precision and provides an ideal ground clearance for loading and unloading the workpieces. The table surface is grooved to form squares. The versatility offered by this type of table makes it possible to easily adapt the different shapes of the parts to be machined with the sealing rubber.

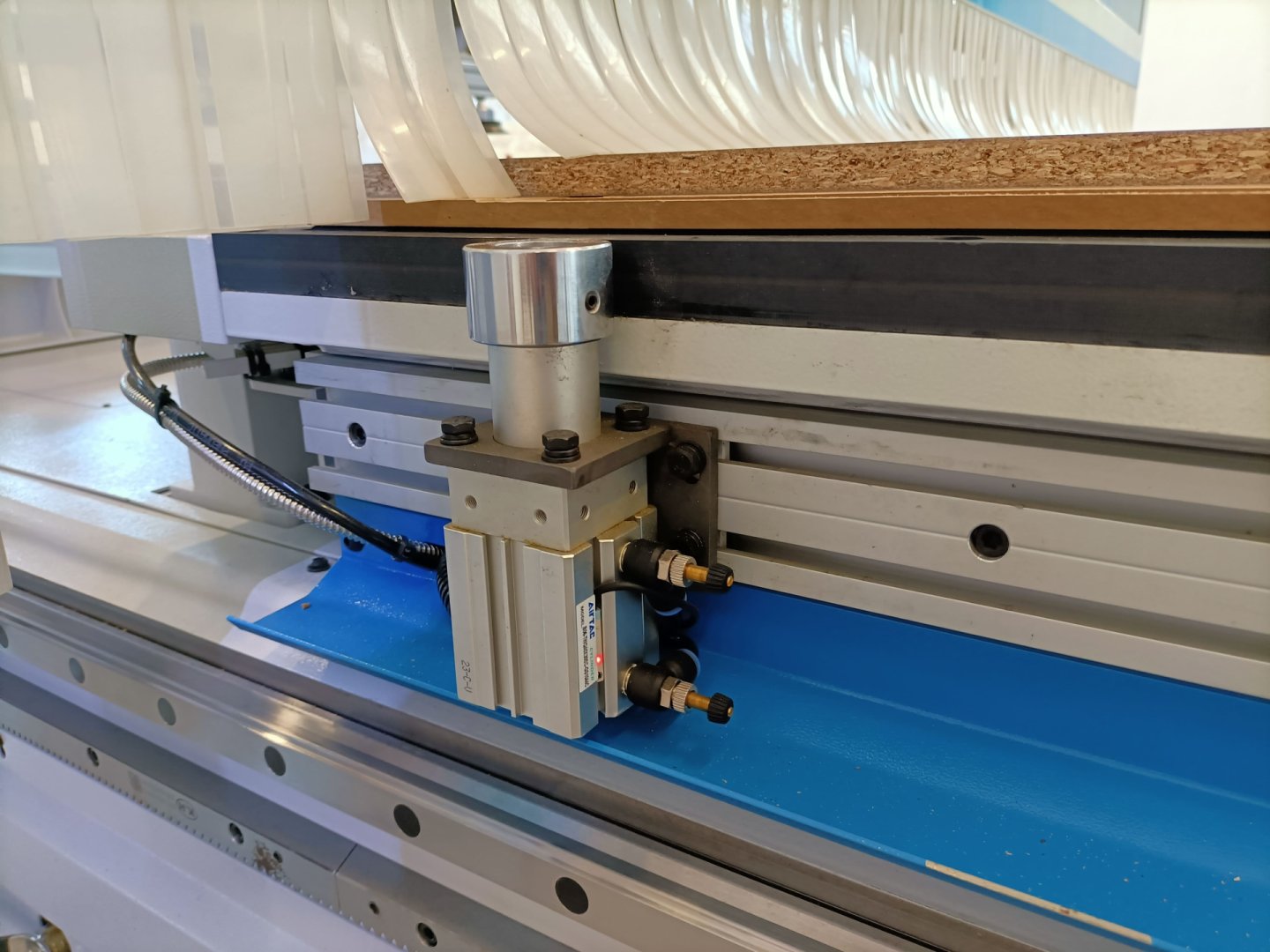

PNEUMATIC BUFFERS

Pneumatic reference stops for precise positioning of the table tops on the table top

Mesa de carga automática con etiquetadora

Ajusta automáticamente la posición de la pieza de trabajo, reconoce la altura delpaquete de tableros mediante un sensor de posición, se eleva/baja automáticamente para ajustarse a la altura.

Etiquetado automático y detección de etiquetas erróneas o faltantes mediante un sensor. Conexión con la descarga automática para establecer una línea de producción de Nesting, reducir los posibles errores y así mejorar la eficiencia de trabajo.

Impresora de etiquetas automática

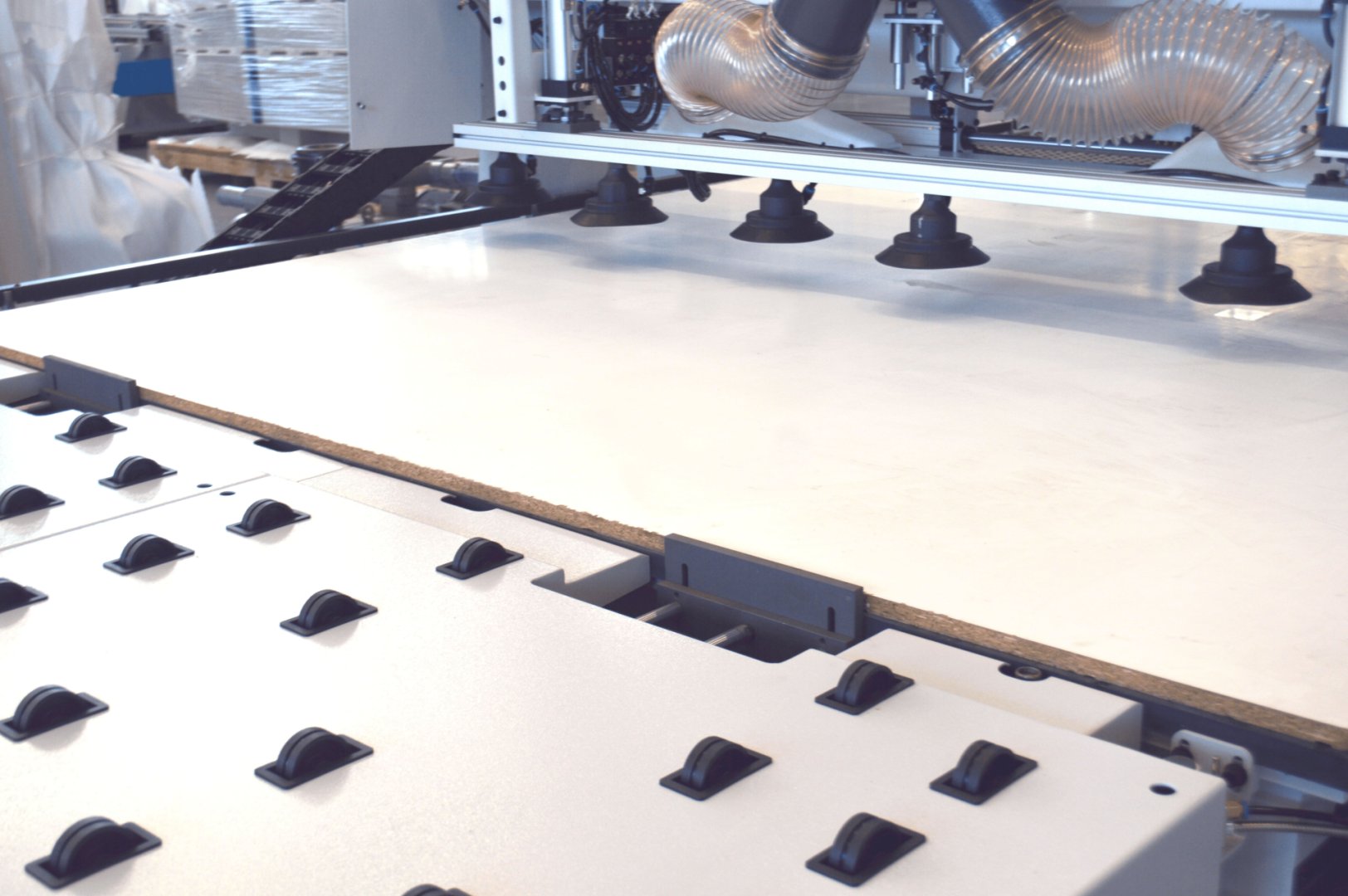

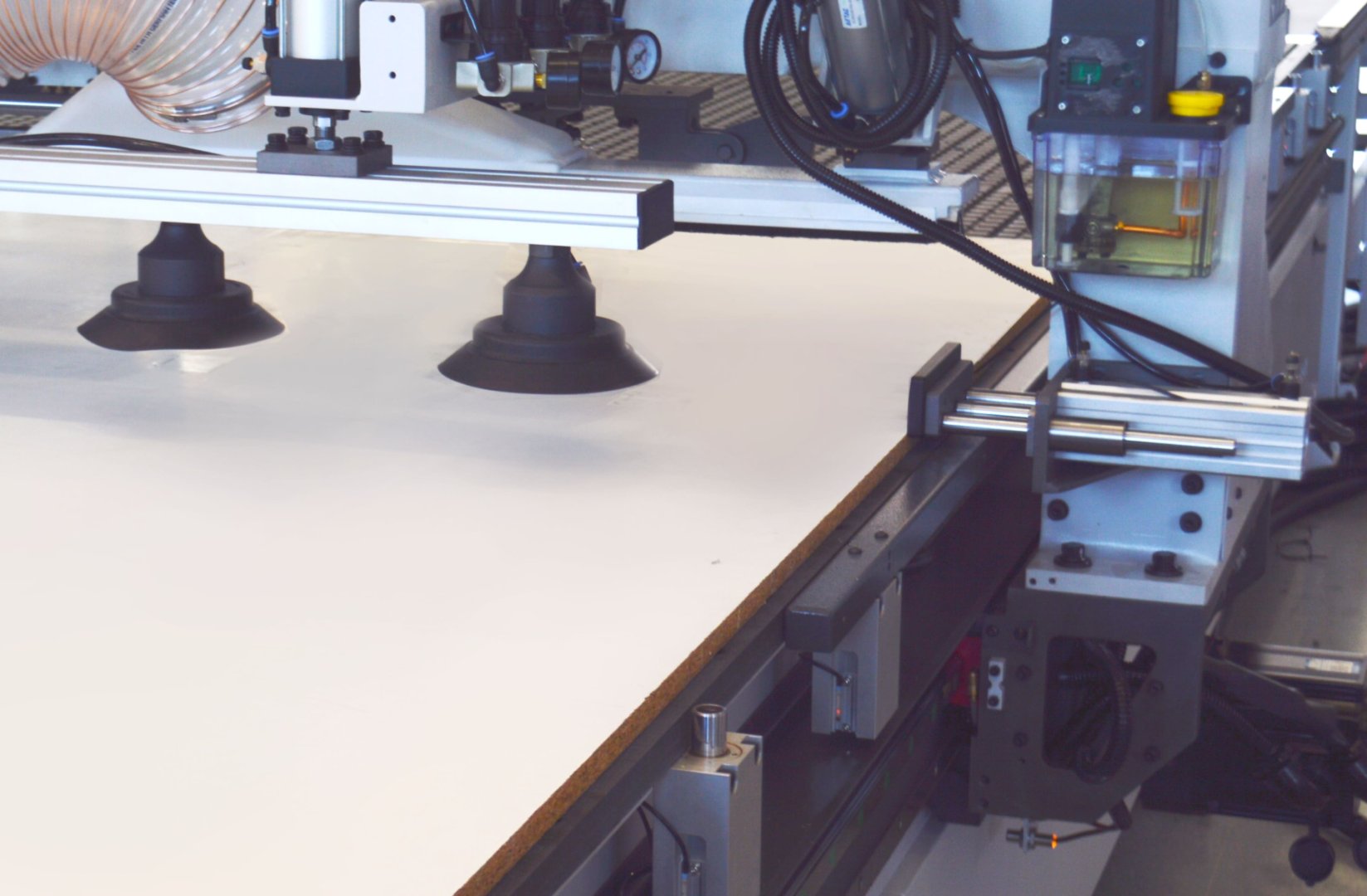

LOAD SUCTION CUPS

The boards are loaded using suction cups at the rear of the gantry.

REAR PUSHERS

Once the suction cups have deposited the board on the table, a set of rear pushers finishes placing the board on the nesting table.

LATERAL ALIGNER

Lateral panel alignment system for perfect positioning and squaring of the panels before starting the nesting work.

FRONT DISCHARGE PUSHER

The pusher is located on the gantry of the machine itself, to adapt to future automatic loading and unloading tables. It has optimised suction nozzles for the ejection of perfectly clean machined panels.

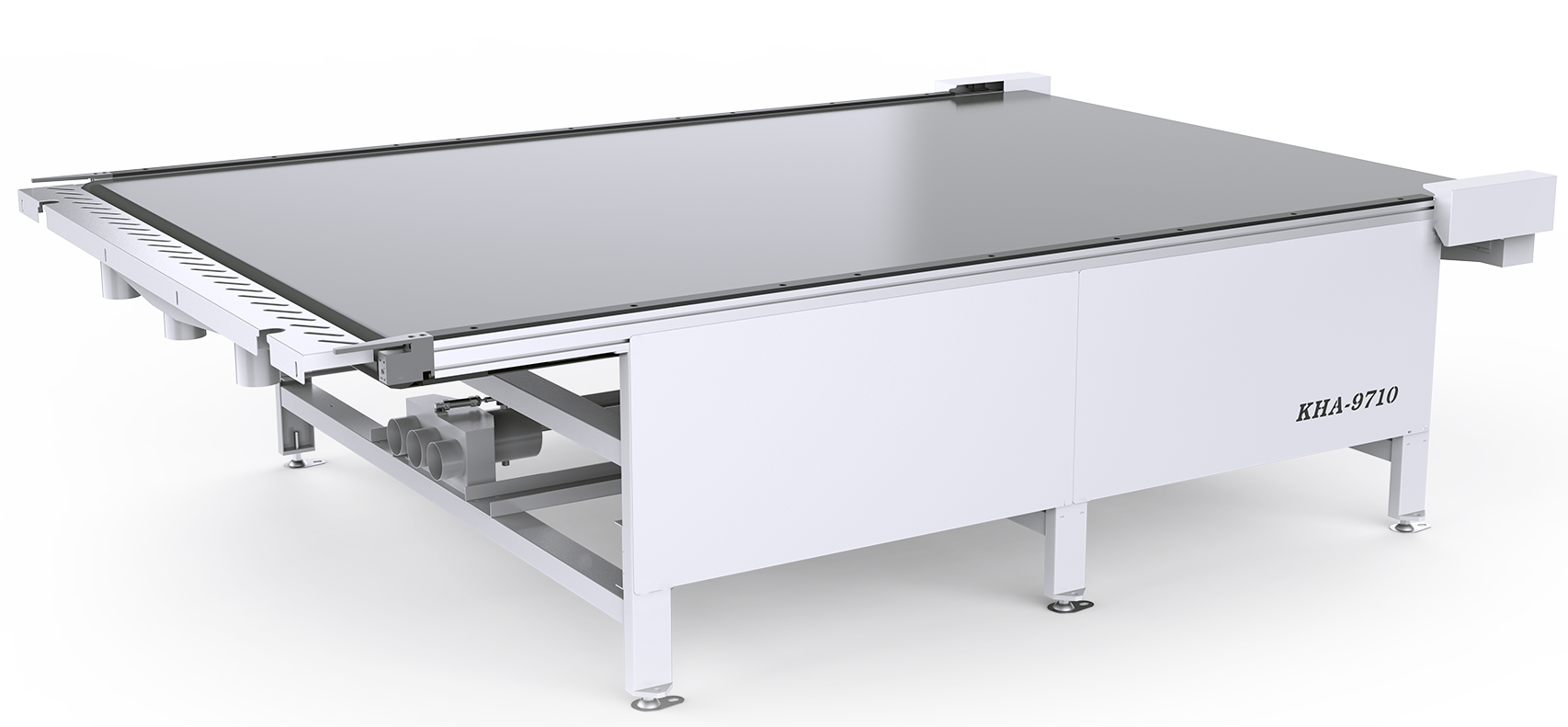

Automatic unloading table

The conveyor belt gently and comfortably discharges the finished parts. The conveyor belt stops automatically and restarts the movement once the panels are removed.

VACUUM VANE PUMPS 244m3/h

Two 244 m³/h rotary propeller vacuum pumps for optimum vacuum generation.

PC INDUSTRIAL COMPUTER SUPPORT MONITOR AND MOBILE CONTROL CONSOLE

Numerical control of the movements of the axes and manoeuvre of the machine. Control PC with CNC design and control software. It manages different parameters such as:

- Tool setting

- Direct reading of files from USB and INTERNAL drives.

- Powerful system for processing and displaying programme files.

Technical Data

Videos

Our machines

KN-3713D loading and unloading machining centre with labelling machine

KN-3713D machining centre loading and unloading

KN-3713D machining centre

Machining centre KN-3710DPC C-axis

KN-3710DE machining centre KN-3710DE Loading and unloading with labelling machine

KN-3710DE Machining centre KN-3710DE Loading & unloading