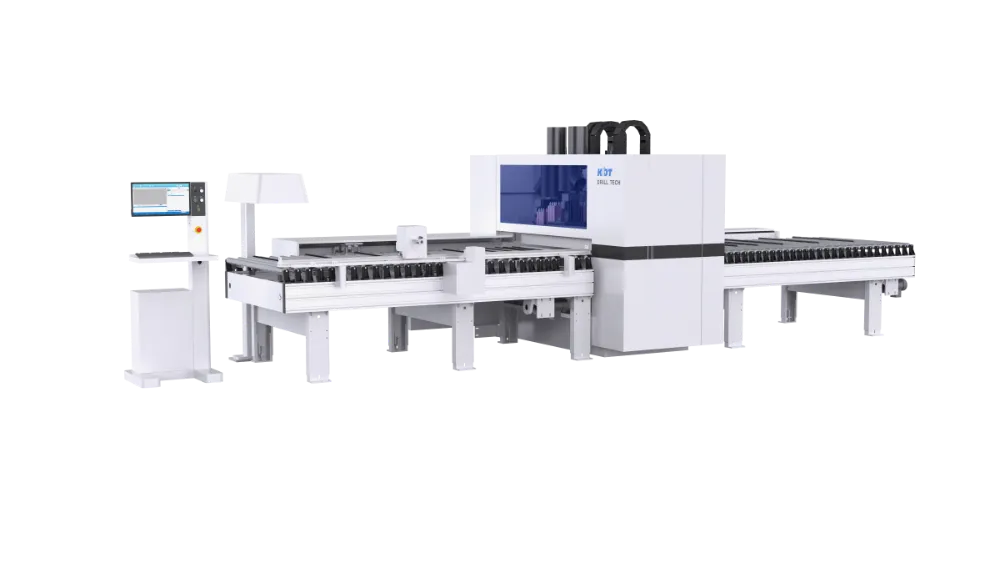

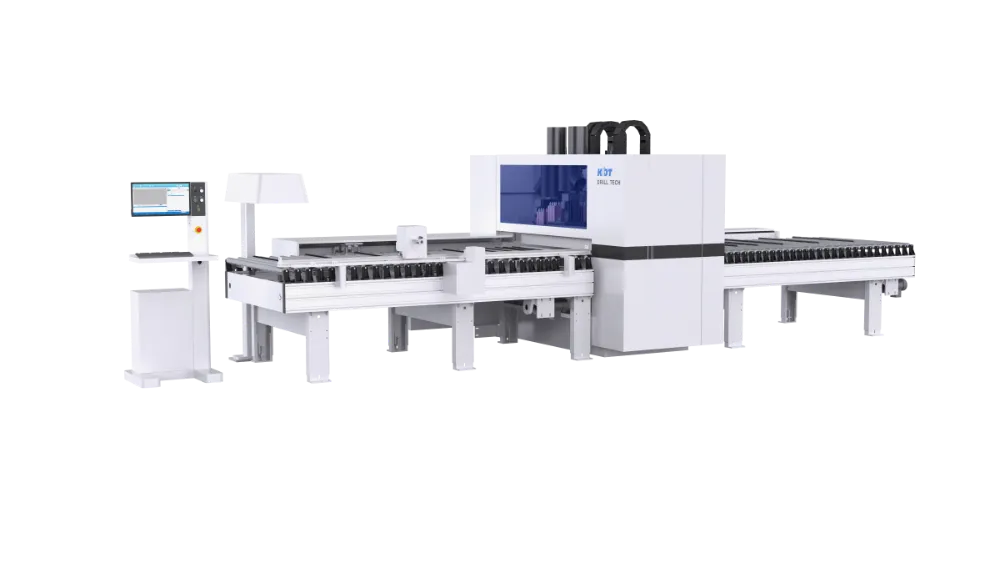

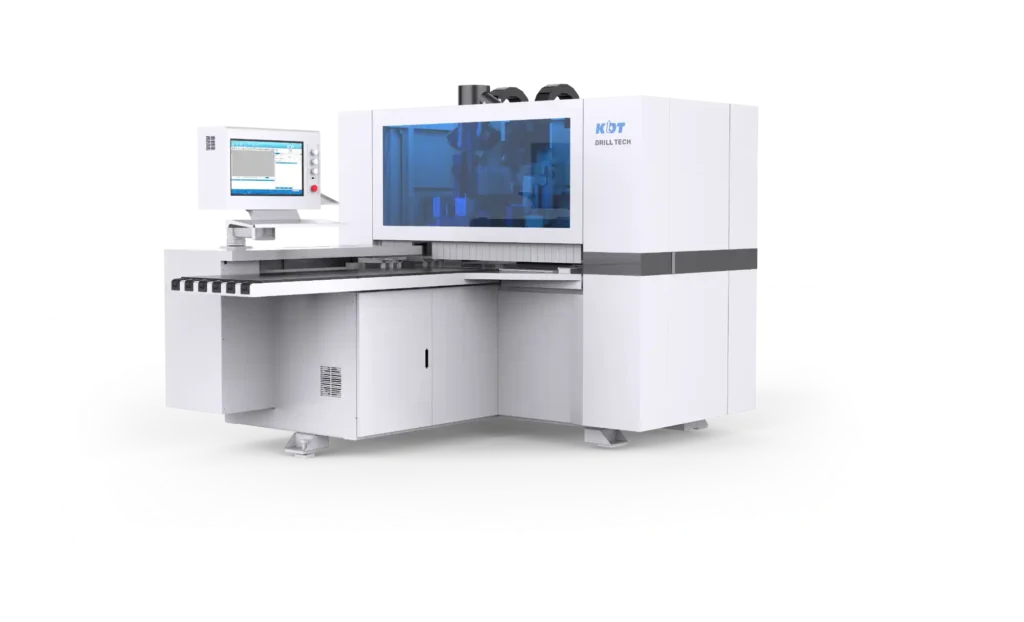

CNC Drill KD-612KHSA

Description

- DOUBLE UPPER DRILLING UNIT WITH MILLING UNIT

- LOWER GROUP OF DRILLS WITH MILLING CUTTER

Intelligent workstation capable of machining one workpiece at a time in different sizes and with different programming.

The efficiency of the CNC 6-sided drilling machine is superior to that of CNC Point-to-Point machines with dual workstations.

Quickly drills vertical/horizontal holes, as well as hinges, half bores, through bores, etc. It can also be used for grooving and milling. It does all this with a double head on the upper side and a complete drilling and milling head on the lower side.

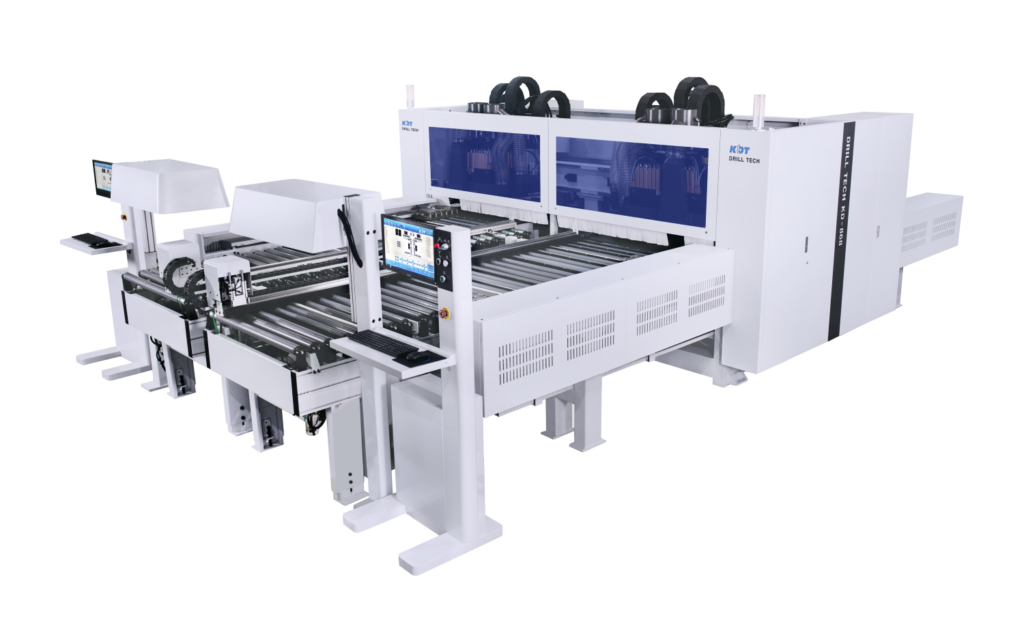

WORKPIECE CLAMPS

Double gripper with long travel for high speed work, up to 140m/min. Movements along the X axis managed by CNC.

The grippers move throughout the process to allow the entire workpiece to be machined. While one is lifted to move, the other clamp holds the workpiece firmly in place to prevent it from moving.

MOBILE AIR CUSHION TABLES

Air cushion tables in two sections that move sideways, moving more flexibly according to the drilling position during the work to avoid scratching or damaging the workpiece or being damaged by the drilling head.

PRECISION LATERAL ALIGNER

Lateral alignment mechanism: ensures greater precision during the process. The aligner is held against the panel surface during the entire process.

DOUBLE ALIGNMENT DEVICE

Fixed positioning by reference stop.

Suitable for small medium size boards, fast positioning.

Intelligent thickness reading through the clamps (Z-axis)

AUTOMATIC DETECTION OF PANEL MEASUREMENT IN X - Y - Z AXES

Automatic precision part measurement system.

This makes machining easier and avoids possible errors.

Photocells for precise reading of part length (X-axis)

WORKING GROUPS

UPPER AND LOWER DRILLING UNITS

Drilling process by means of two upper drilling units and milling unit.

In top composition and 9 vertical drills and a milling cutter.

MILLING TECHNOLOGY

Structured milling device with double pressure plate (patented)

Improves milling accuracy and reduces panel scratches on the surface.

Double-sided work and mirror function.

Simultaneous drilling of 2 panels. Milling and corner recesses.

PRE-SCANNER FEED TABLE

Facilitates the entry of parts into the line

BARCODE READER SCANNER

A powerful scanner at the entrance of the line reads the label of the part where the work to be done is indicated on the surface of the board.

The drill will start working according to the instructions on the label.

Grooving unit

The standard machine is not equipped with these items unless otherwise stated.

SIERRA GROUP

Fast grooving by disc. Can groove from 50 to 850mm.

PC CONTROL AND WORK SOFTWARE

PC control with user-friendly CAD/CAM.

Intelligent AI optimisation system, automatically calculates the optimal processing path, and adds simulation effects.

MACHINE BED

Hardened welded monoblock frame to relieve all internal material stresses, very robust and machined on precision centres to ensure that all vibrations are absorbed and provide stability during machining.

REAR SIDE WASTE DISCHARGE CONVEYOR

Facilitates cleaning and maintenance of the machine.

SAFETY DEVICES

The machine is supplied with all safety devices in accordance with current CE regulations to ensure safe operation at all times.

Technical Data

THE MANUFACTURER RESERVES THE RIGHT TO MAKE CHANGES WITHOUT PRIOR NOTICE.

The technical data and characteristics mentioned in this offer are of an informative nature and may be subject to modifications, updates and improvements.

Videos

Documents

Our machines

CNC Drill KD-612KHZ

KD-868A CNC Drill

CNC Drill KD-812ZA

KD-812A CNC Drill

CNC Drill KD-612KHSZA

CNC Drill KD-612KHSZ

CNC Drill KD-612KHSA

CNC Drilling Machine KD-612KHS

CNC Drill KD-612KH

KD-612G CNC Drill

KD-610R CNC Drill

CNC Drill KD-610HZ

KD-610H CNC Drill