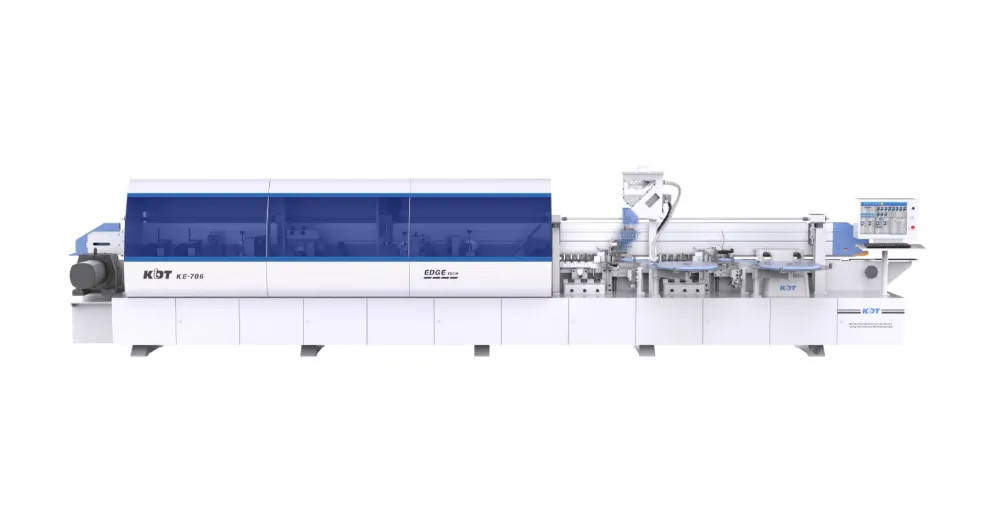

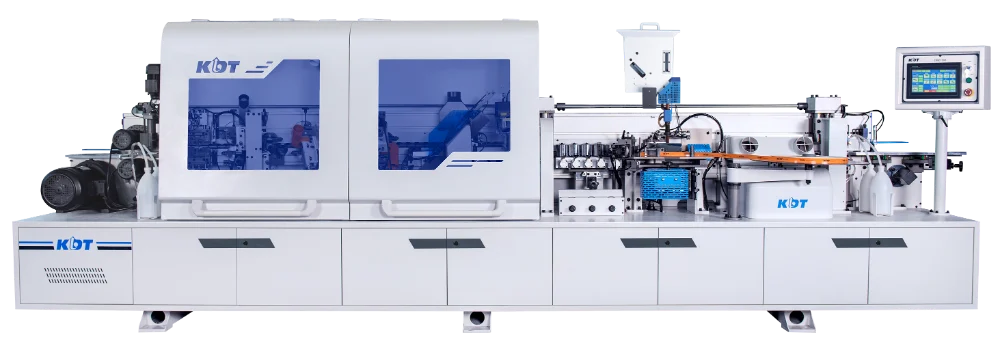

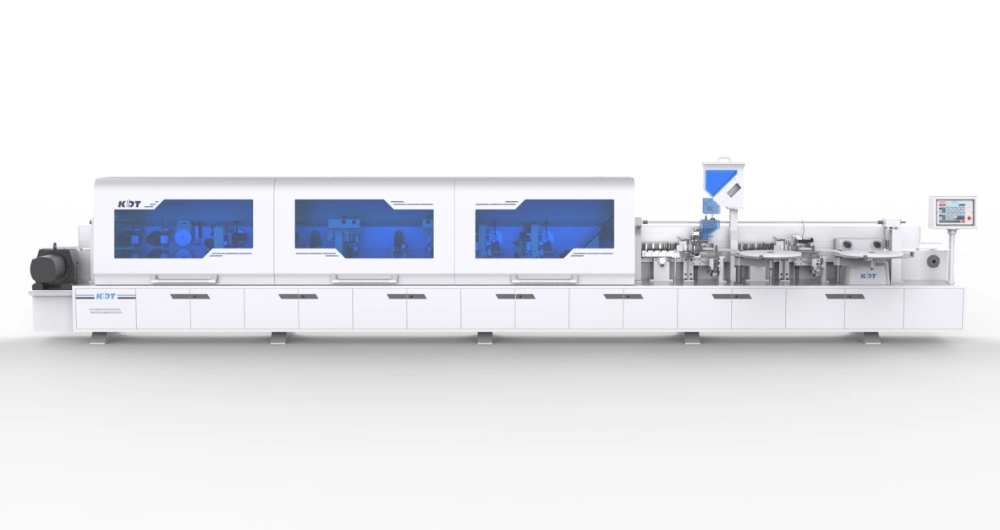

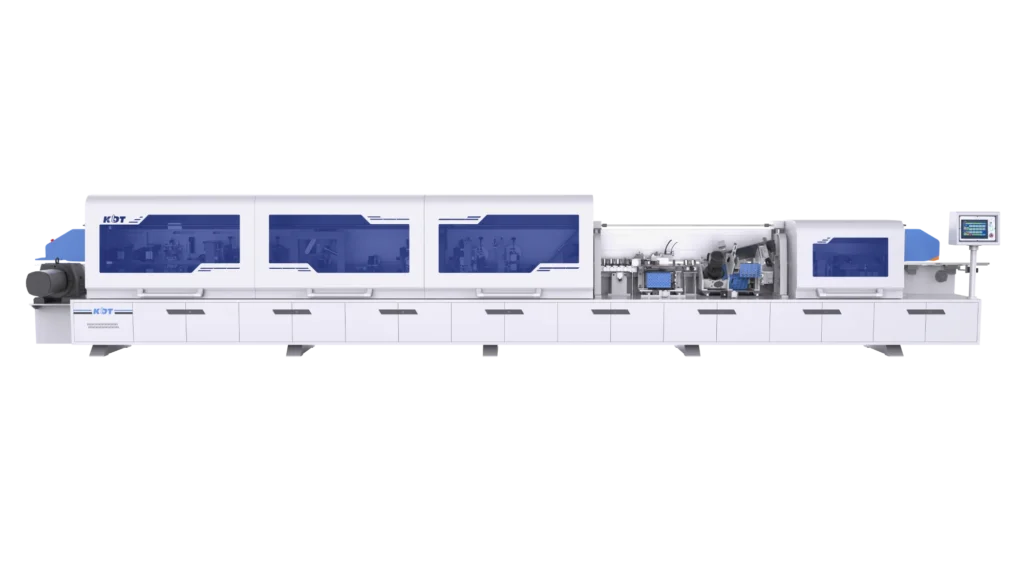

Edge banding machine KE-706B

Description

CNC CONTROL FOR WORK GROUPS

This is an innovative, very easy and intuitive system designed to facilitate the work of the operator who, at the touch of a button, can change the thickness of the edge, perfectly adjusting the work units, greatly reducing the time spent on the adjustment and achieving excellent finishes from the first piece.

It also has an excellent aid for making the initial settings on the machine whenever a new type of edgebanding is added: the "fine control".

Servo-driven numerically controlled automatic positioning system with servomotors

FINE CONTROL

Operator assistance device for positioning the working units to their exact position. With its high precision, it is able to make a very fine adjustment according to the actual thickness of the edge.

It is a mobile device, which allows the operator to comfortably visualise the operation of the unit to be adjusted during the adjustment itself, thus achieving unequalled finishes.

UPPER PRESSURE BRIDGE

Built on a steel frame, it has a wide rubberised belt mounted on swivel bearings for agile linear movement of the workpiece and optimum clamping.

This group is positioned motorised and is displayed on the machine's screen.

MOTORISED ENTRANCE GUIDE

Large, chrome-plated steel ruler, with double support on prismatic guides and servo-driven numerical control positioning.

Automatic positioning from the PC control.

SOPORTE PORTARROLLO GIRATORIO

Con plato para el posicionamiento de los rollos de PVC – ABS y tiras de formica previamente cortadas, con carga manual y alimentación automática.

EDGE LOADER AND SHEARER

For fine edging rolls up to a maximum of 3mm. The machine is supplied with a rubber roller for use in rolls.

INDEPENDENT AND MOBILE EDGE FEEDING SYSTEM

Asegura la longitud del canto sobrante delante y atrás de la pieza. Alta eficiencia y precisión en la alimentación del canto.

INDUSTRIAL PC MACHINE CONTROL

Simple operation and diversified functions, customised machining packs. Operators can select the machining programme that best suits their needs at the touch of a button.

On the industrial PC we can store an infinite number of working memories.

NON-STICK SPRAY DEVICE

Spray system installed on the machine with dust-resistant nozzles. Glue residues are prevented from adhering to the workpiece.

TUPI GROUP AT THE ENTRANCE

Positioned before the gluing unit to rectify the edge of the board and eliminate chipping due to a bad cut, obtaining an optimum surface for gluing.

IR LAMP

It allows rapid heating of the panel face, improving the adhesion of the glue, even in unfavourable environmental conditions of temperature and humidity.

GRUPO DEPÓSITO DE COLA CON PREFUSOR

Para cola termo fusible EVA con calentamiento rápido. Termo-regulador digital para el control de la temperatura del depósito de cola.

Con el dispositivo PREFUSOR conseguimos el máximo aprovechamiento de la cola en las mejores condiciones.

DEPÓSITO DE COLA

Depósito accesorio integrado en el chasis que se encuentra situado debajo del calderín y que es un almacén de cola. Un sensor dará la señal para detener el llenado de cola en el prefusor.

GRUPO PRESIÓN

Compuesto por cuatro rodillos de presión neumática para garantizar una perfecta adherencia del canto aplicado.

Numerical control positioning system.

Self-adjusting mechanism.

Automatic pressure adjustment according to the different requirements of the gluing process.

SUCTION ENDOSUCTION UNIT

Precise rapid unit consisting of two motors for cutting the excess edge of the panel. With automatic positioner from the control panel with the possibility of changing the position of the motors from 0º to 15º.

GRUPO RIBETEADOR FINO CNC

Compuesto por 2 de motores de alta frecuencia independientes. Cada uno de los motores disponen de copiadores verticales giratorios de gran diámetro y copiadores cónicos horizontales para obtener un perfilado perfecto.

Posicionador automático mediante servomotores desde el panel de mandos con la posibilidad de cambiar la medida del espesor del canto.

Automatic change of tool position by servomotor.

ROUNDING UNIT

Pneumatic rounding unit

Allows automatic rounding of the applied edge angles, without the need to stop the workpiece Two-position automatic edge thickness changeover system.

Optimum finishes, with the ability to adapt to different board profiles without special adjustments or programming of the device.

RADIO WIPER UNIT

For a perfect finish on PVC-ABS edges up to 3 mm, eliminating all edge corrugations.

Automatic positioning from the control panel by servomotor.

Exclusion from the group from the table

Automatic tool change

One-button changeover on the machine, intelligent and efficient operation.

Automatic changeover between R1- R2 scraper and adjustment by servomotor.

FLAT TAIL SCRAPER UNIT

Upper and lower tail scraper group.

Equipped with feeler discs.

CLEANING SPRAY

Líquido de limpieza. Con la aplicación del limpiador antes de los discos pulidores de paño se eliminan restos de cola sueltos.

GRUPO PULECANTOS

Compuesto por 2 motores independientes de 0,18kW trabajando a 1400 RPM para facilitar la limpieza y el brillo del canto.

Technical Data

Videos

Documents

Our machines

Single-side gluing machine KE-706GBSU Laser

Single-side gluing machine KE-706GB

Single-side gluing machine KE-706 CNC

Single-side gluing machine KE-668JSGAU (45)

Single-side gluing machine KE-668JGB

One-side gluing machine KE-665JSKA

Single-side gluing machine KE-665JHSKA

One-side gluing machine KE-655JSKA

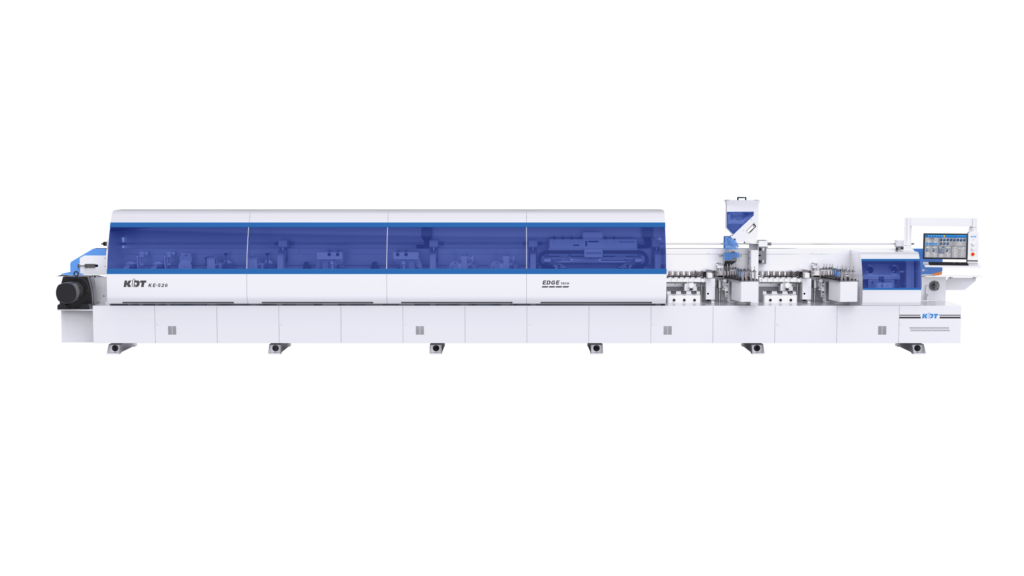

Single-side gluing machine KE-526G

Single-side gluing machine KE-520GU

Single-side gluing machine KE-496GH

Single-side gluing machine KE-493G (40)

Single-side gluing machine KE-493 (40)

Single-side gluer KE-468JSKGA (45)

Single-side gluer KE-468JSKGA

Single-side gluer KE-468JHSKGA (45)

Single-side gluer KE-468JHSKGA

Single-side gluing machine KE-399JB

Single-side gluing machine KE-396JB

Edge banding machine KE-706B